MILBON ORIGIN STORY: PART 2

part two of the milbon origin story will BE all about visiting MIe Prefecture.

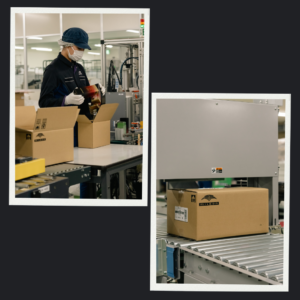

We had the pleasure of visiting the Yumegaoka Factory to see and understand how Milbon manufactures, ships, and handles the products. Milbon’s key mission is to consistently produce reliable, high-quality products for millions of people around the world.

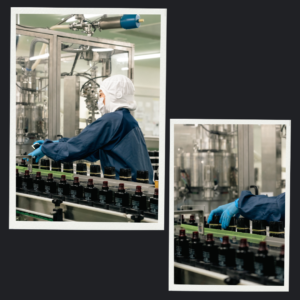

It’s one of the places where the ideology ‘Made By Milbon’ comes to life. When something is ‘Made By Milbon’ they want consumers to know that each of their hundreds of products are backed by advanced technology and an outstanding attention to detail.

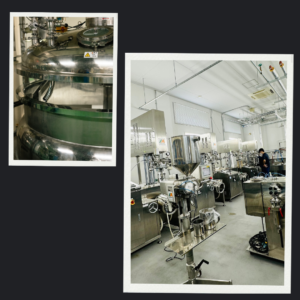

Their manufacturing process begins with ‘scaling up’ original formulations that were first created in the size of a beaker at their lab and producing the same great formulations at four tons its size.

In order to reproduce each product, they begin by weighing out large quantities of raw ingredients, sometimes 20-30 ingredients at a time, and through various stages of prototyping to test its efficacy at a molecular level, they are able to create products in tanks up to 200 kilograms in size. This rigorous scale-up process is highly complex, resulting in product consistency and ensured quality control.

Having developed their own advanced production technologies, which have been modified to accommodate the production of haircare products for professionals and consumers, Milbon prides themselves on having an industry edge that proves they’re a forceful competitor in the haircare industry!